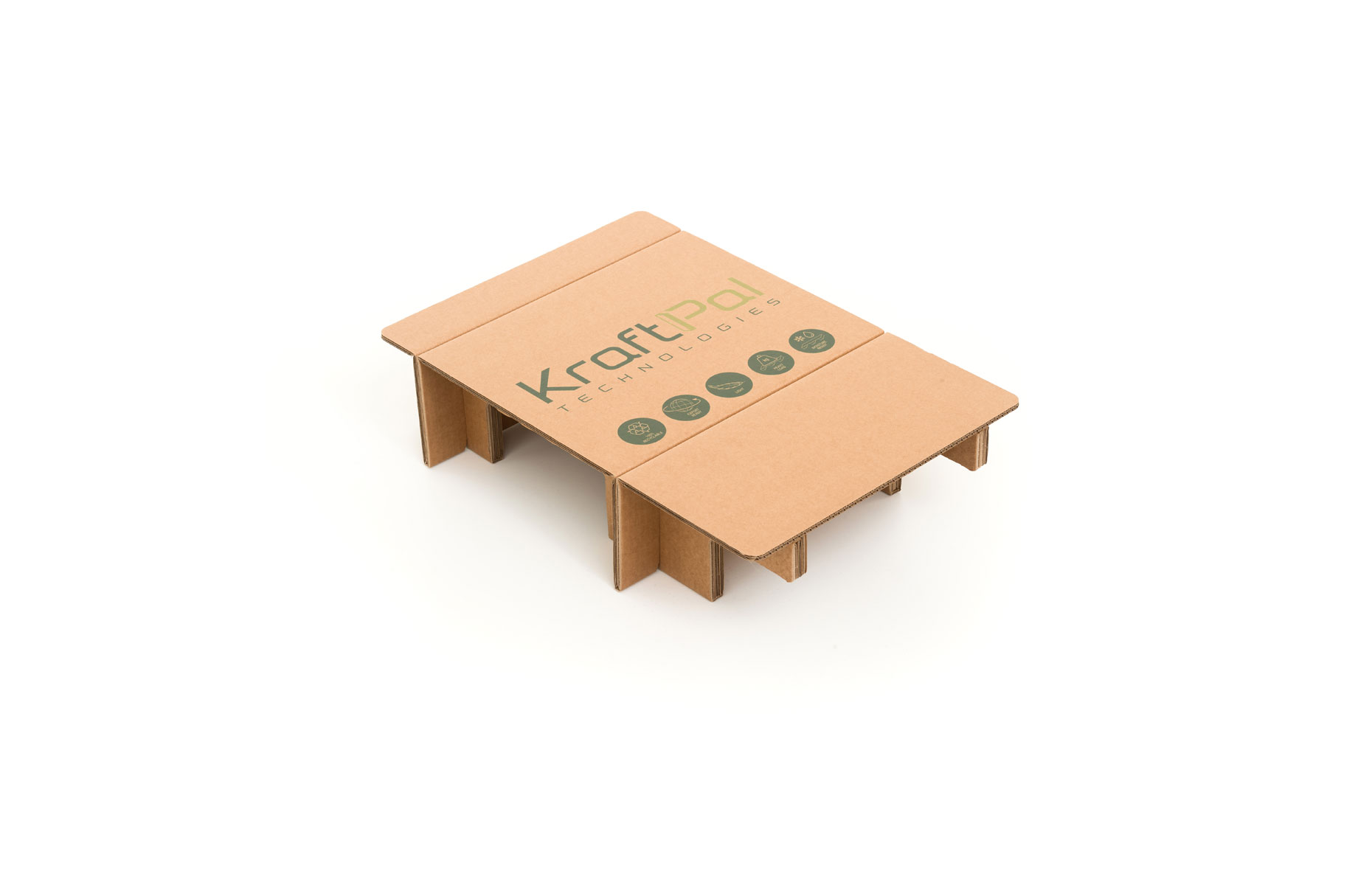

Corrugated Cardboard Pallets

Perfect alternatives to wood, composite, plastic and all other pallets currently on the market.

Being ultra-light, KraftPal pallets combine all important cost-saving advantages with the normal strength and durability of traditional solutions. Our mass-production process allows us to deliver in quantities meeting even the most demanding packaging and shipping needs. Best and most important news of all, clients are able to switch to KraftPal pallets without making changes to their existing processes or equipment.

We tailor our solutions to meet our clients’ needs.